Danger Signages

Introduction

DANGER NOTICE PLATE is one of the mandatory Signage as per Rule No. 35 of the Indian Electricity Rules on the transmission line to provide proper indications about the electricity phases or signals like high voltage or high-tension wires, gateways, and walls at required places.

Danger Signage installation at the workplace is one of the mandatory steps in the interest of human safety also. It alerts all occupants about the hazardous situation, if avoided, will result in death or severe injury. OSHA wants to make all audiences and workers aware of the risk involved in the specific area of the workplace. The Danger Notice Plate identifies the high-risk area and extreme caution to be taken by all employees. Apart from this, Danger Sign Boards are essential in locations where there is a risk of open electrical wiring or naked wires.

It has been observed that at Danger Notice Plates of different sizes, different designs have been installed at various locations. BIS has adopted an IS standard for DANGER NOTICE PLATES to cover the standardized features of notice plates in line with IE Rule 35. Some essential requirements and tests are necessary to meet satisfactory performance and function of Danger Notice Plates. Secondly, as per Rule No. 35 of the Indian Electricity Rules, the owner of every medium, high, and extra high voltage must install Danger Sign Board as per Standard IS: 2511 permanently at a place that is visible from a long distance and communicates mass audience.

Our Products

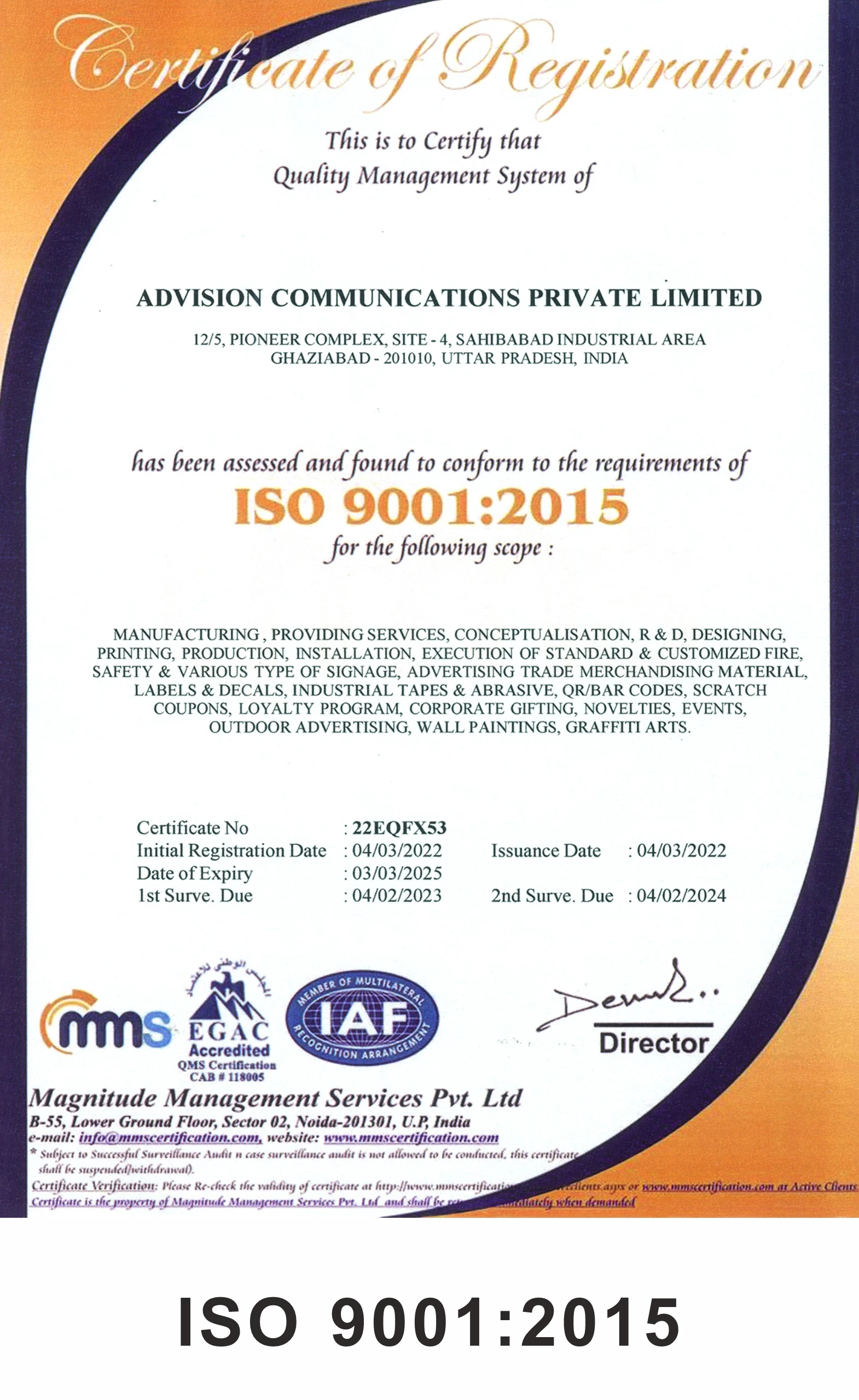

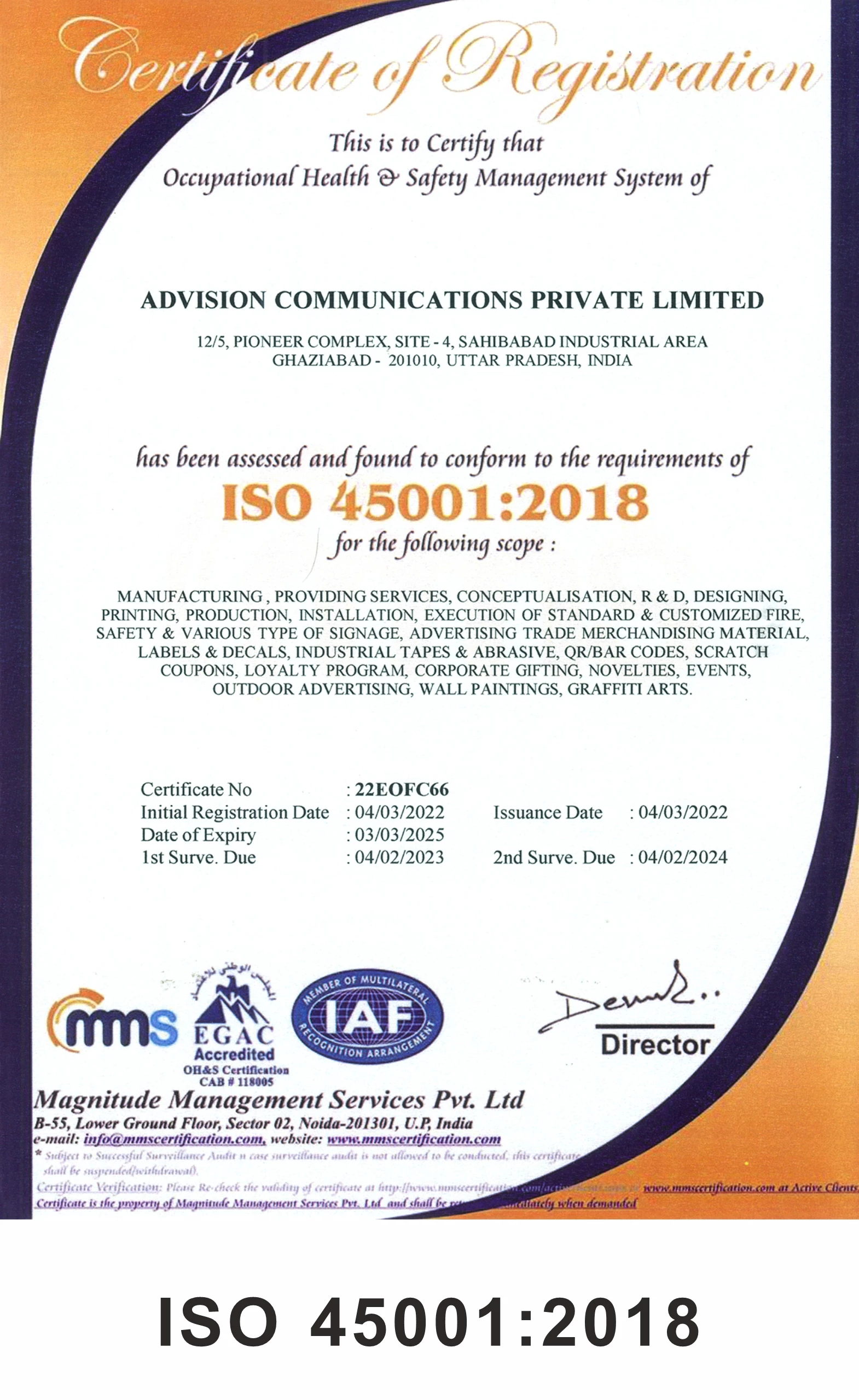

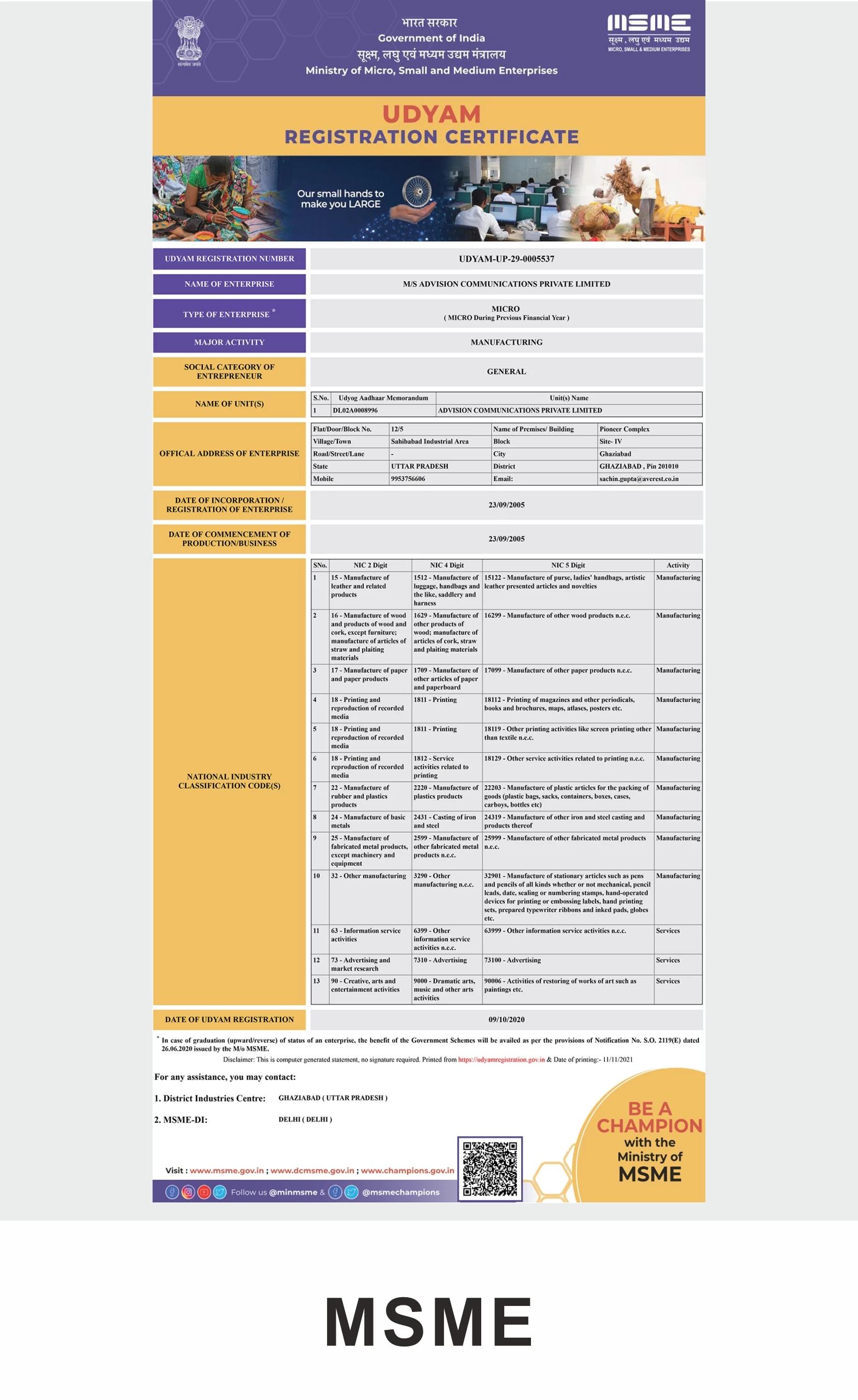

Sun-Signs® is the leading manufacturer and exporter of Danger Signage as per Safety Standard IS: 2551 & other international Standards. We manufacture Danger Notice Plates, Danger Stickers, and Danger Sign Boards as per the Volt requirements of the client in all Indian district languages & International languages. Sun-signs® provides premium quality 440V Metallic Danger signage Plates, 440V Danger Signage Plate, and 11000V Danger Notice Plate (Hindi/ English to Local language) to various reputed departments. We also provide customized Self-Adhesive Safety Tape with Printed Messages of Danger in Multi Languages as per client specifications. All Danger signages are well tested as per the Safety Norms.

|

|

|

|

|

|

|

| Danger Plate 1500 VDC English Hindi |

Danger Plate 415 V Hindi Kannada |

Danger Plate 1100 V Hindi Kannada |

Danger Plate 415 V English Kannada |

Danger Plate 1100 V English Kannada |

Danger Plate 415 V English Malyalam |

Danger Plate 1100 English Malyalam |

|

|

|

|

|

|

|

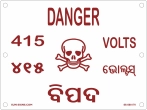

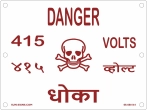

| Danger Plate 415 V English Odia |

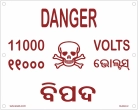

Danger Plate 1100 V English Odia |

Danger Plate 415 V English Bangla |

Danger Plate 11000 V English Bangla |

Danger Plate 1500 V English Tamil |

Danger Plate 11000 V English Tamil |

Danger Plate 415 V English Marathi |

|

|

|

|

|

|

|

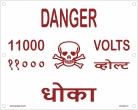

| Danger Plate 11000 V English Marathi |

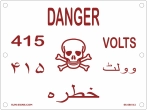

Danger Plate 415 V English Urdu |

Danger Plate 11000 V English Urdu |

Danger Plate 415 V English Punjabi |

Danger Plate 11000 V English Punjabi |

Danger Plate 415 V English Hindi |

Danger Plate 11000 V English Hindi |

|

|

|

|

|

|

|

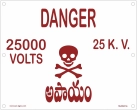

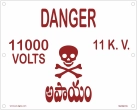

| Danger Plate 25000 V English Telugu |

Danger Plate 11000 V English Telugu |

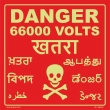

Danger Plate 66000 V Multi – Language |

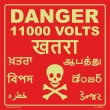

Danger Plate 33000 V Multi – Language |

Danger Plate 66000 V Multi – Language, Glow in Dark |

Danger Plate 33000 V Multi – Language, Glow in Dark |

Danger Plate 11000 V Multi – Language, Glow in Dark |

Applications

Danger Notice Boards are typically displayed in workplaces, public spaces, construction sites, and other areas where there is a need to inform and protect people from potential dangers. Here are some applications of danger notice boards:

- Construction Sites: Danger notice plates are prominently displayed at construction sites to warn workers and visitors about various hazards such as falling objects, heavy machinery, high voltage areas, or slippery surfaces. These signs help prevent accidents and ensure the safety of individuals on the site.

- Industrial Facilities: Manufacturing plants, oil and gas industry, warehouses, and factories often have numerous potential hazards. Danger Notice Boards are used to identify areas with dangerous equipment, chemicals, high-temperature zone, high noise levels, radiation hazards, or restricted access zones. They serve as a constant reminder for employees and visitors to exercise caution and follow safety protocols.

- Roadways and Traffic: On roads and highways, Roadside Danger Notice Boards are used to alert drivers about potential dangers such as sharp curves, pedestrian crossings, animal crossings, road work zones, low visibility areas, or areas prone to landslides. These signs help motorists stay alert and take appropriate precautions while driving.

- Laboratories and Research Facilities: Research labs and facilities dealing with hazardous materials, biohazards, or radioactive substances utilize Danger Notice Boards to indicate restricted areas, biohazardous material storage, or the presence of potentially harmful substances. These signs remind individuals to follow proper safety procedures and wear appropriate protective equipment.

- Electrical Installations: In areas with high-voltage equipment or electrical installations, 440 V DANGER NOTICE SIGN BOARDS are used to indicate the presence of live electrical currents, electrical shock hazards, or areas where unauthorized personnel are not allowed. These signs warn individuals to exercise caution and prevent accidents.

- Hazardous Material Storage Areas: Facilities that handle or store hazardous material such as chemical plants, warehouses, or laboratories, install Hazardous Materials Danger Signages to identify areas where dangerous substances are stored. These signs provide essential information about the risk and nature of the hazard and the precautions to be taken to ensure safety.

It’s important to note that the specific design and content of danger notice boards may vary based on local regulations, industry standards, and the nature of the hazards involved. The purpose is always to communicate potential dangers effectively and encourage individuals to act safely and responsibly in the given environment.

Danger Notice Plates

As per IS: 2551 Safety Standard, Danger Notice Plates have the following attributes:

- Dimension– Two sizes of Danger Notice Plates are recommended as mentioned below:

- For display at Medium Voltage Installation – 200*150 mm

- For high and extra high voltage Installation – 250*200 mm

- Material – The plate is made with 1.6 mm thick mild steel and vitreous enameled white. The letters, figures, and skull with crossbones are in Red Colour (Follows IS: 2551).

- Language – The text of Danger Notice Plate plays a vital role in better understanding mass audiences. All lettering must be centre place and uniformly written. The word denote “Danger” is written in the Universal Language Hindi or English and is recommended equal to other regional languages.

- Marking – Essential information like Identification of the manufacturer, Standard Mark shall be mentioned on the plate so that it does not interfere with the main message on the signage.

- Height-DANGER PLATES as per IS 2551 should be affixed permanently in a conspicuous position on every motor, generator, transformer, and other electrical equipment at a height of 3 m from the ground.

Colour and Test for Danger Notice Plates

Colour of Danger Sign Plates

As per IS 5:2007 Colours for Ready Mixed Paints and Enamels – Signal Red Colour (No-537) is significantly used in Danger Signage as it has the highest wavelength and is least scattered. Red colour travels the longest distance through rain, mist, and fog. As per standard, there are 104 colours for ready-mixed Paints and Enamels. The Danger Sign is Red and associated with other colours like Black and White.

“Danger” Plates should pass the essential testing as per IS:2551

- Visual Examination – The notice plate is examined for visual conformity concerning work, letter, position, size, and colour.

- Dimensional Check – Check for the conformity ofthickness, size, and placement of letters and figures.

- Test for Weather Proofness – Methodsof Test for Colour Retention as specified in IS 8709:1977.

Sun-signs® developing an in-house testing facility to cover all mandatory testing to meet the requirement of IS standards. Sun-signs® aim to supply high-quality Danger Notice Board to meet IS 2551 Standard in Power Transmission line.

OUR SUCCESS STORIES

>Installation of Photoluminescence Over Bridge at the Redevelopment Site near AIMS Flyover

The Introduction

In May 2018, NDMC has given the responsibility to redevelop one of the Green Islands in South Delhi near the AIMS flyover. NDMC has decided to commence the construction of the biggest cascading fountain at the site.

The Challenge

While the construction work is going on, the civic agency has installed and operated a treatment plant at the basement of the construction site to provide crystal clear and odour-free water running across the fountain. They lay down heavy motors, water pumps with a wide network of pipelines for the successful running of the water treatment process. The zone is a dark and fire-sensitive area.

There is a need to install Photoluminescence Fire Safety Signages and an Emergency Exit Route Map in the basement for the safety of the technicians and workers.

The Solution

To overcome this concern, SUNSIGNS raises the safety awareness solution for all the technicians and workers working in the basement. Putting up Glow in Dark Signages, Battery-Backed Sign Boards with 8 hrs, and 440v Nightglow Signages were not enough. We have designed a Fire Exit Plan that instructs the fastest escape route for all occupants in any emergency.

SUNSIGNS offers to install a “Glow in Dark Over Bridge” that enhances the visible in day and night. The proposal for Night Glow Over Bridge has been approved by NDMC officials.

The assignment was given to SUNSIGNS by the client. As per the emergency escape route plan, we have installed Photoluminescence Over Bridge that allows smooth movement over the pipeline network in the area.

The product is a premium quality Night Glow Metal Bridge with photoluminescence outlines. The photoluminescent paint emits a green glow in the dark and highlights the Metal Bridge. It absorbs light to get charged during the day and glows at night. Lacquer coating spray over the metal bridge gives an anti-tamper and scratch-proof protection with a long-lasting finish. This Night Glow Over Bridge enhances visibility from all distances with a long glow time.

The Result

SUNSIGNS is appreciated and rewarded by NDMC for the successful completion of the assignment. With no power supply or battery backup, the Photoluminescence Over Bridge glows at night for as long as 6 to 8 hrs. The application has a long service life, is resistant to harsh weather, and requires no maintenance. Thus, installing Fire Exit Plan and Night Glow Over Bridge has proven the most appropriate emergency exit solution for technicians working at the redevelopment site.

” A Safe Exit Plan with Glow in Dark Over Bridge “ – Successful Completion of the Assignment by SUNSIGNS.

>Arcelor Mittal HARIJA PLANT (SURAT)

The Introduction

Installation of CONFINED SPACE ENTRY SIGNAGE BOARD

AM/NS India is a joint venture between the world’s well-known and leading steel organizations- Arcelor Mittal, and Nippon Steel. An integration from Iron ore to ready-to-market products. With over three hundred steel grades, serves an array of industries like agriculture, automotive, infrastructure, defence, energy, and many more. All the technicians and workers at Harija Plant work under hot temperatures, converting raw steel into fabrication like Sheets, Roles, Plates Chequered Steel, and Pipes.

The Challenge

Because of the high temperature (300-400 Degrees) workstation and looking at the safety of all employees, there is a need to instruct and guide employees about the safety measures mandatory while working at Steel Plant. In addition, it is essential to restrict the entry of visitors into the heat zones.

The Solution

Overcome this concern, SUNSIGNS proposes a safety solution for technicians and workers working at hot temperatures in Harija Plant. A restricted entry at the Steel Plant. Propose to install a CONFINED SPACE ENTRY SIGNAGE BOARD was approved by HARIJA PLANT officials.

SUNSIGNS provides a CONFINED SPACE ENTRY SIGNAGE BOARD to be installed at Arecelor Mittal Nippon Steel Plant. Our signages are as per National and International Safety Standards and meet the client requirement specification as follows:

- UV Protection-We use high gloss UV coating on signage board.

- Heat Resistant– PP coating and High Specific Epoxy Coating protect signages from elevated temperatures (300- 400 Degrees). All our signages are well tested for heat resistance.

- Epoxy Coated– We do Epoxy Coating at the top of every Signage that enhances the outdoor life of the Signage. It protects the sign board from Fog, Dust. Average Outdoor Durability: 8 to 10 years

- Anti-tamper and Anti – Scratch: Lacquer Coating and Epoxy Coating gives a super fine finish with Anti-tamper.

- Spot Glow in Dark– The text, Sign, and Symbol are printed with UV Protected Photoluminescence Ink. The signage glows in the dark or at night with bright green light. Thus, the Glow in Dark application boosts the performance of the Signage. The signage works efficiently for a 24/7 time span.

- Direct Printing: We do premium quality Direct Printing, an add-on value to the signage. No use of stickers and No peel-off.

- Protect Colour Fade– UV Cure Ink, Colour Fade Resistant Coating on both sides.

- Harsh Weather Resistant

- Abrasion Resistance

The Result

SUNSIGNS is appreciated and rewarded for the successful completion of the assignment. With no power supply or battery backup, the Photoluminescence Confined Space Entry Signage Board glows at night for up to 8 hrs. The application has a long service life, heat resistant and requires no maintenance. Thus, installing Confined Space Entry Signage Board has proven the most appropriate safety solution at the HARIJA PLANT.

“Installation of Confined Space Entry Signage Board at Arcelor Mittal HARIJA PLANT(SURAT)” –

Successful Completion of Assignment by SUNSIGNS

1. What is a Danger Signage ?

A Danger Signage refers to a visual warning or indication designed to alert individuals about potential hazards or dangers in a particular area. It typically consists of a distinctive symbol or pictogram accompanied by text or additional graphical elements. Danger signage is commonly used in workplaces, public spaces, and other environments to promote safety and prevent accidents.

2. Why Danger Sign is Red ?

Red Color is defined as warning color as per ISO, BIS, OSHA and all other international standards too & Red color has the greatest wavelength and travels the longest distance through fog, rain, and air particles. Moreover, Red Color scatters the least and thus the instruction is visible and readable from long distance in all weather conditions.

3. What is the difference between Danger Signage and Warning Signage?

| 1. Danger Signage | 2. Warning Signage |

| 3. Serious hazard | 4. hazard |

| 5. If ignored, cause serious injury or death | 6. If ignored, cause injury |

| 7. Degree of Risk is highest | 8. Degree of Risk is High or Moderate |

4. When Should Danger Signs only be used ?

Danger Signage should be installed only where an immediate hazard exists.

5. What is the purpose of Danger Signage?

The primary purpose of danger signage is to communicate the presence of potential hazards or dangers to individuals to prevent accidents, injuries, or even loss of life. By providing clear and concise visual cues, danger signage helps raise awareness about specific risks, prompts people to take necessary precautions, and encourages adherence to safety protocols.

6. What are some common symbols used in Danger Signages ?

Danger signage often employs universally recognized symbols or pictograms to convey the nature of the hazard. Some common symbols used include:

- Skull and crossbones: Indicate the presence of toxic or poisonous substances.

- Lightning bolt: Represents electrical hazards or high voltage areas.

- Flame: Indicates the presence of fire or flammable materials.

- Exclamation mark: Used for general warning purposes.

- Falling object: Signifies the risk of objects falling from above.

- Triangular hazard symbol: Generally used to alert individuals of potential dangers or hazards in a specific area.

7. Where can Danger Signage be found ?

Danger signage can be found in a wide range of environments, including:

- Workplaces: Industries such as construction sites, manufacturing plants, chemical facilities, and warehouses often use danger signage to warn employees about various hazards present on the premises.

- Public Spaces: Parks, recreational areas, and public buildings may utilize danger signage to highlight potential dangers, such as uneven terrain, slippery surfaces, or deep water.

- Roadways: Traffic signs and road markings serve as danger signage to warn drivers of potential hazards, such as sharp turns, steep inclines, or pedestrian crossings.

- Laboratories: Research facilities and laboratories use danger signage to indicate areas with biohazards, radioactive materials, or other potentially harmful substances.

- Hazardous Areas: Areas with high-voltage equipment, confined spaces, or machinery may feature danger signage to ensure proper precautions are taken.

8. Are Danger Signs Standardized Internationally ?

Yes, to a certain extent. While danger signage may have variations in design and specific symbols based on regional or national regulations, there are international standards and conventions that provide guidance for the design and use of safety signs. For example, the International Organization for standardization (ISO) has developed standards such as ISO 7010, which provides a set of pictograms and design principles for safety signs, including danger signs. These standards aim to promote consistency and facilitate understanding across different countries and industries.